Solutions

Discover automation solutions built specifically for cookware manufacturing. From PTFE and ceramic coating lines to automotive and aerospace applications—Kratos delivers precision at every stage. Our systems are engineered for speed, consistency, and scale. Whether you’re upgrading a single process or automating your entire plant, we’ve got you covered. Explore smart, industry-ready solutions designed to transform your production line.

Automation Solutions for Every Coating Line

From PTFE cookware to aerospace components, our automation systems are engineered for precision and efficiency. Explore customized solutions for every application—designed to boost productivity and product quality across industries.

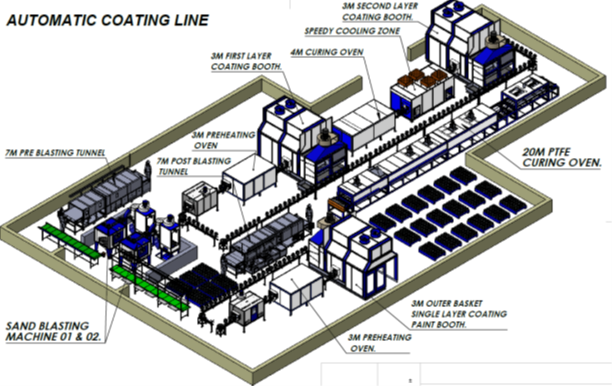

Automatic Coating line

Kratos Automations specializes in fully automatic coating lines designed for high-volume cookware manufacturing. Our solutions integrate washing, shot blasting, PTFE/ceramic coating, curing ovens, and robotic material handling into a seamless, continuous process. With PLC-controlled automation, precision spray systems, and energy-efficient ovens, we ensure uniform coating quality and consistent throughput. From concept to commissioning, we deliver ready-to-run automatic coating lines backed by training, support, and long-term reliability.

SHOT BLASTING MACHINES

Kratos Shot Blasting Machines are engineered to deliver uniform, controlled surface preparation that enhances coating adhesion, durability, and final finish quality. Designed for automatic coating lines, the system uses high-pressure reciprocating air shot blasting with multiple Y-type blast guns to achieve consistent roughness across the workpiece. With PLC-based control, indexing turntable handling, and efficient dust collection, the machines ensure reliable performance, operator safety, and production capacities of 500–800 pieces per hour.

WASHING TUNNELS

Kratos Washing Tunnels are designed for high-efficiency, multi-stage precision cleaning of metal components prior to coating or assembly. The continuous tunnel system combines high-pressure spray washing, effective filtration, controlled heating, and hot-air drying to ensure complete removal of oils, grease, and surface contaminants. With PLC-based automation, adjustable conveyor speeds, and SS 304 construction, Kratos washing tunnels deliver consistent cleaning quality, reduced water consumption, and reliable performance for outputs of up to 1,000 pieces per hour.

Dry Type Paint Booths for Aerospace & Automotive Applications

Kratos Dry Type Paint Booths are engineered for aerospace and automotive applications, delivering clean, controlled painting environments for both manual and automatic operations. Designed with high-efficiency dry filtration and balanced airflow, the booths ensure superior surface finish, consistent film build, and excellent overspray capture. With PLC-based controls, dedicated AHUs, and robust safety systems, Kratos paint booths offer an eco-friendly, low-maintenance solution that meets stringent industrial standards while enhancing productivity and operator safety.

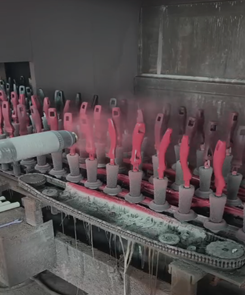

Automatic Handle Coating Line

The Automatic Handle Coating Line is engineered for high-speed, uniform coating of cookware handles, delivering consistent finish quality with minimal manual intervention. The system integrates surface preparation, automatic spray coating, controlled curing, and synchronized material handling into a continuous, fully automated process. With PLC-based controls, adjustable curing parameters, and flexible conveyor options, the line ensures repeatable quality, optimized cycle time, and production capacities of 400–1,000 handles per hour, tailored to different handle designs and coating requirements.

INDUSTRIAL OVENS

Kratos Industrial Ovens are engineered for precise, reliable thermal processing across PTFE, ceramic, enamel, and specialty coating applications. Available in conveyorized and batch configurations, these ovens feature electric heating, thyristor/PID-based temperature control, efficient hot air recirculation, and robust insulation to ensure uniform curing, high energy efficiency, and safe operation. Designed to integrate seamlessly with automatic coating lines or standalone processes, Kratos ovens deliver consistent results, flexible operation, and compliance with industrial safety and thermal standards.

Assembly Conveyors & Roller Conveyors

Kratos Assembly & Roller Conveyors are designed to deliver smooth, efficient, and ergonomic material flow across coating lines, ovens, and assembly operations. Built with robust steel construction, variable speed control, and modular configurations, these conveyors reduce manual handling, improve operator comfort, and support high-throughput production. Seamless integration with automation and a wide range of accessories ensure reliable performance, flexible layouts, and optimized workflow efficiency.

Heading 8

Description for tab two.

Pollution Control Equipment & Emission Management Systems

Kratos Automations offers a comprehensive range of Pollution Control Equipment engineered to maintain clean, safe, and regulatory-compliant industrial environments. Our solutions effectively manage dust, fumes, VOCs, and process emissions generated from coating, blasting, grinding, and thermal operations. Designed with high-efficiency filtration, robust construction, and low maintenance requirements, Kratos systems ensure reliable performance, long service life, and sustainable operation in demanding industrial applications.

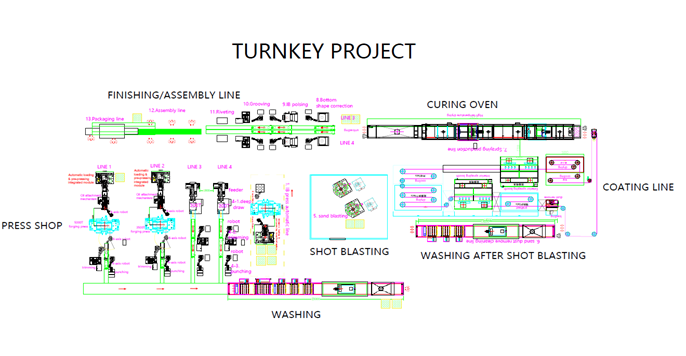

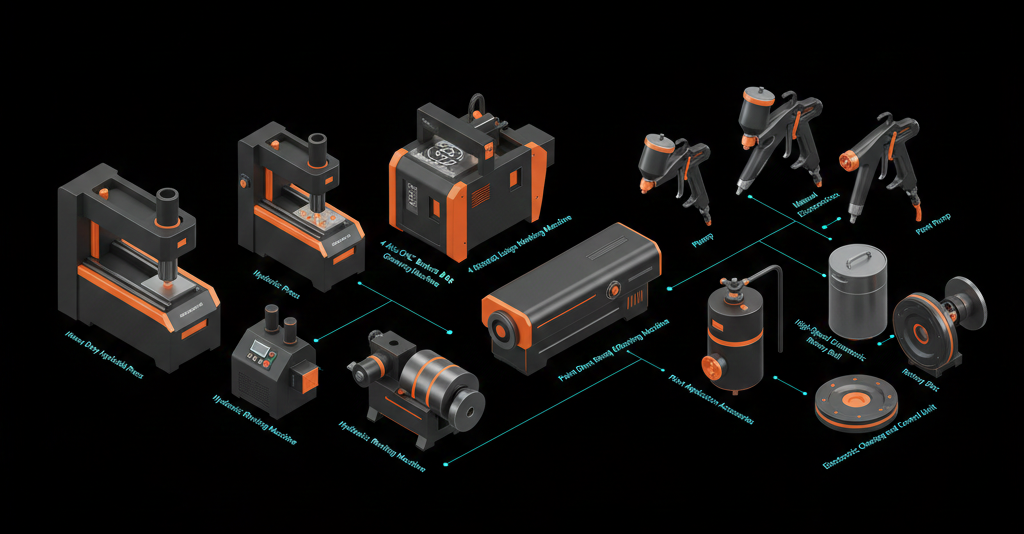

Additional Systems & Equipment for Turnkey Projects

Kratos Automations offers a comprehensive range of additional systems and industrial equipment that complement our turnkey coating and manufacturing solutions. From heavy-duty and servo hydraulic presses, CNC trimming and grooving machines, laser marking and riveting systems, to paint preparation and advanced electrostatic application accessories, our products are engineered for precision, durability, and seamless integration. These systems enable customers to build complete, high-performance production lines with improved productivity, consistent quality, and long-term operational reliability.

Chat to our team

Chat with our automation specialists for quick answers, product guidance, or help finding the right solution for your cookware manufacturing needs.

Why Manufacturers Trust

Kratos Automations

We’re not just machine builders—we’re automation partners. With deep industry focus, tailored engineering, and proven results across global factories, Kratos helps cookware manufacturers work smarter, faster, and more efficiently.

Industry-Specific Expertise

We specialize exclusively in cookware manufacturing automation. From coating lines to grooving machines, our solutions are purpose-built—not repurposed.

Custom Engineering for Every Plant

No two factories are the same. That’s why we design, build, and fine tune every system to match your specific process, space, and production goals.

Reliable Support & Global Reach

We serve clients across India, the Middle East, and Southeast Asia with fast, responsive technical support and long-term maintenance you can count on.

How We Build Automation That Works for You

Every factory is different. That’s why we follow a structured yet flexible process—understanding your workflow, engineering the right solution, and supporting you every step of the way.

Step 1

Understand Your Needs

We start by learning about your factory, challenges, and production goals.

- Initial consultation call or site visit

- Review of your current workflow and pain points

- Define scope of automation and key objectives

Step 2

Design & Deliver the Right Solution

We engineer custom systems tailored to your cookware production line.

- 3D modeling, simulation, and layout planning

- Machine manufacturing, testing, and optimization

- Quality checks and final approvals before shipment

Step 3

Install, Train, and Support

We ensure smooth setup, train your team, and offer long-term service.

- On-site installation and commissioning

- Operator and technician training

- Ongoing support, maintenance, and upgrades

Automation Solutions for Every Coating Line

Have questions about our automation systems, installation process, or capabilities? We’ve answered the most common queries to help you better understand how Kratos can support your cookware manufacturing goals.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Get Expert Advice, Industry Trends, and

Automation Insights – All in One Place

Stay updated with expert insights, real-world case studies, and the latest trends in cookware manufacturing automation. Whether you’re upgrading a single machine or planning a full plant transformation, our articles deliver the knowledge you need to move smarter and faster.

Subscribe to Our Newsletter

Get the latest updates on cookware automation, product innovations, industry news, and expert insights—delivered straight to your inbox. Join the Kratos network and stay ahead in manufacturing.