Additional Systems & Equipment for Complete Turnkey Manufacturing

Kratos Automations offers a comprehensive portfolio of additional systems and specialized equipment that complement our turnkey automation and coating solutions. From high-capacity hydraulic presses to precision machining, marking, fastening, and paint application systems, our products are engineered to deliver performance, accuracy, and seamless integration across modern manufacturing lines.

Heavy Duty Hydraulic Presses (2000T – 5000T)

Kratos Heavy Duty Hydraulic Presses are designed for high-force forming applications requiring exceptional structural strength, precise pressure control, and long-term operational safety. Built with pre-stressed frame construction and servo-controlled hydraulic systems, these presses deliver reliable performance under ultra-high working pressures.

| Item | Specification / Description |

|---|---|

| Capacity Range | 75T / 100T / 120T / 150T / 200T / 250T / 300T / 350T |

| Customization | Machine parameters are customizable as per application requirements |

| Drive System | Servo motor–driven hydraulic system |

| Servo Control Technology | The servo motor drives the main transmission oil pump, precisely controlled by a servo controller and high-accuracy sensors |

| Energy Efficiency | Compared with conventional hydraulic presses, the servo hydraulic press achieves up to 30% energy savings |

| Positioning & Repeatability Accuracy | Repeated positioning accuracy up to ±0.01 mm, effectively reducing rejection and material wastage |

| Speed & Productivity | Servo drive enables optimized running speed; overall production efficiency is approximately 35% higher than conventional motor-driven CNC hydraulic presses |

| Pressure Control | Precise pressure regulation through closed-loop servo control |

| Operational Benefits | Lower noise level, reduced heat generation, stable long-term performance |

CNC Bottom & Edge Grooving Machines

Kratos CNC Grooving Machines are designed for automatic trimming and grooving of cookware components, ensuring precision, consistency, and efficient scrap handling. Servo-driven axes enable simultaneous operations with high repeatability.

| Parameter | Specification |

|---|---|

| Machine Type | 3-Axis Automatic Cookware Edge Trimming & Grooving Machine With Scrap Compactor |

| Maximum Workpiece Size | Ø 450 mm |

| Suitable Workpiece Height | 30 – 200 mm |

| Main Motor Power | 4 kW |

| Spindle Speed Range | 100 – 3000 rpm |

| Axis Travel – X(1) | 220 mm |

| Axis Travel – Z(1) | 240 mm |

| Axis Travel – X(2) | 100 mm |

| Axis Travel – Z(2) | 100 mm |

| Drive System | Servo motor–driven axes |

| Working Air Pressure | 0.6 MPa |

| Machine Dimensions (L × W × H) | 1650 × 1050 × 2050 mm |

| Machine Weight | Approx. 1250 kg |

| Processing Capability | Simultaneous automatic trimming and grooving |

| Application | Cookware edge trimming and grooving operations |

Laser Marking Machines

Kratos Laser Marking Machines provide high-speed, permanent, and maintenance-free marking for cookware and metal components. Fiber laser technology ensures excellent marking clarity and long operational life.

| Parameter | Specification |

|---|---|

| Control System | Computer-based control system |

| Laser Power | 50 Watt |

| Laser Type | Fiber Laser (typical for industrial marking) |

| Marking Area | 110 × 110 mm to 300 × 300 mm (lens dependent) |

| Marking Speed | Up to 10,000 mm/s |

| Cooling Mode | Air Cooling |

| Marking Accuracy | High precision, permanent marking |

| Marking Content | Text, logo, serial number, QR code, bar code |

| Application | Cookware, metal components, industrial parts |

| Operation Mode | Automatic / Manual |

| Maintenance Requirement | Low maintenance, long laser life |

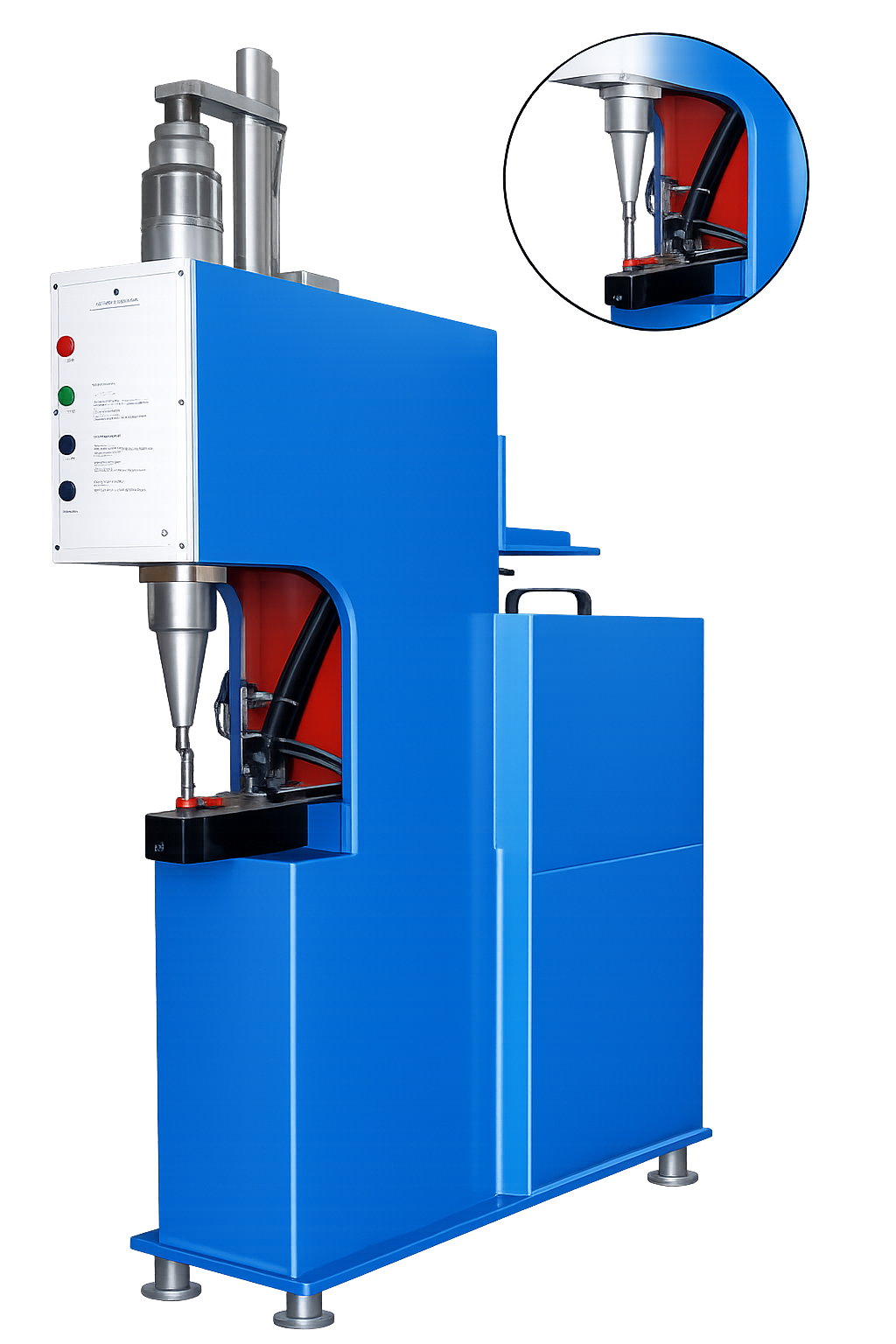

Riveting Machines

Kratos Riveting Machines are engineered for accurate and consistent fastening of handles and components in cookware manufacturing. Controlled hydraulic force ensures uniform rivet formation and long-term joint reliability.

| Parameter | Specification |

|---|---|

| Machine Type | Hydraulic Riveting Machine |

| Application | Riveting of handles and components for cookware |

| Workpiece Size Range | Ø 140 mm to Ø 400 mm |

| Master Cylinder Force | 20 Ton |

| Hydraulic Cylinder Stroke | 150 mm |

| Drive System | Hydraulic |

| Installed Power | Approx. 4 kW |

| Operation Mode | Semi-automatic / Automatic (as applicable) |

| Accuracy | Consistent rivet forming with controlled force |

| Safety Features | Two-hand operation / safety guards / emergency stop |

| Customization | Machine parameters customizable as per rivet and product design |

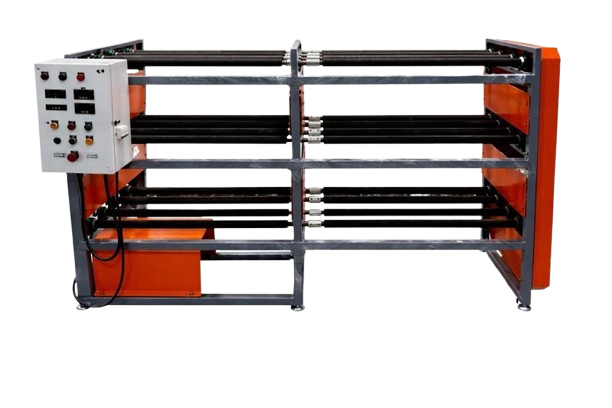

Paint Drum Rolling Machines (Ceramic / Sol-Gel Coatings)

Kratos Paint Drum Rolling Machines ensure uniform mixing of ceramic and sol-gel coating materials prior to application. Controlled rotation prevents sedimentation and maintains stable coating viscosity.

| Parameter | Specification |

|---|---|

| System Type | Continuous Multi-Stage Washing Tunnel |

| Throughput Capacity | Up to 1,000 pieces per hour |

| Control & HMI System | PLC-based control system with color HMI touch panel for machine operation, parameter setting, alarms, and diagnostics |

| Conveyor Speed | 0 to 1.5 m/min (Variable) |

| Workpiece Size | Diameter: 160 mm to 350 mm Height: 15 mm to 150 mm |

| Spray System | High-pressure spray nozzles with uniform coverage |

| Heating System | Electric Heating |

| Drying Temperature | Up to 120 °C |

| Material of Construction | SS 304 |

| Filtration System | Individual Y-type strainers with filters on each spray pipe; frame-type filter at pump inlet |

| Safety Features | Level sensors, interlocks, emergency stop system |

| Washing Process Flow | Loading → Pre-Degreasing → Degreasing → Cold Water Rinse-1 → Cold Water Rinse-2 → Hot Water Rinse → Air Knife → Drying Oven → Unloading |

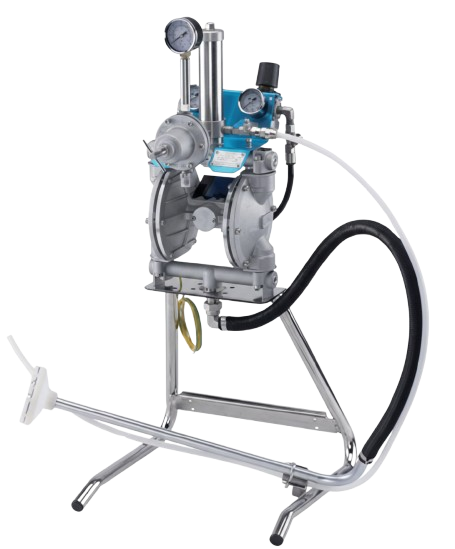

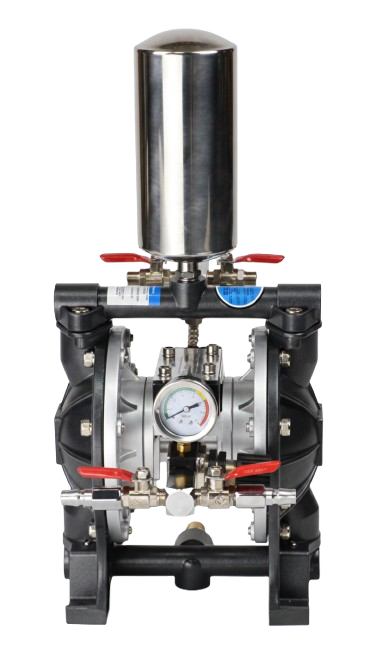

Paint Application Accessories & Electrostatic Systems

Through authorized partnerships with Anest Iwata, Manoli, and HDA, Kratos supplies a complete range of high-performance paint application accessories for PTFE, ceramic, and conventional coating systems. These accessories ensure high transfer efficiency, reduced paint consumption, and consistent finish quality, fully compatible with Kratos spray booths, coating lines, and curing ovens.

Spray Gun 1

Spray Gun 1

Paint Pump 1

Paint Pump 2

Pressure Pot 1

Pressure Pot 2

High Speed Electrostatic Rotary bell

Disk High Speed Electrostatic Rotary Disc

Automatic Air Static Gun

Manual Electrostatic Spray Gun

Charging and Control Unit

Chat to our team

Chat with our automation specialists for quick answers, product guidance, or help finding the right solution for your cookware manufacturing needs.

Why Manufacturers Trust

Kratos Automations

We’re not just machine builders—we’re automation partners. With deep industry focus, tailored engineering, and proven results across global factories, Kratos helps cookware manufacturers work smarter, faster, and more efficiently.

Industry-Specific Expertise

We specialize exclusively in cookware manufacturing automation. From coating lines to grooving machines, our solutions are purpose-built—not repurposed.

Custom Engineering for Every Plant

No two factories are the same. That’s why we design, build, and fine tune every system to match your specific process, space, and production goals.

Reliable Support & Global Reach

We serve clients across India, the Middle East, and Southeast Asia with fast, responsive technical support and long-term maintenance you can count on.

Automation Solutions for Every Coating Line

Have questions about our automation systems, installation process, or capabilities? We’ve answered the most common queries to help you better understand how Kratos can support your cookware manufacturing goals.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.