Material Handling & Conveyor Systems for Automated Production Lines

Kratos Material Handling & Conveyor Systems are designed to ensure smooth, synchronized, and efficient movement of components across coating lines, ovens, and assembly processes. Our conveyor solutions improve workflow efficiency, reduce manual handling, and support high-throughput manufacturing environments.

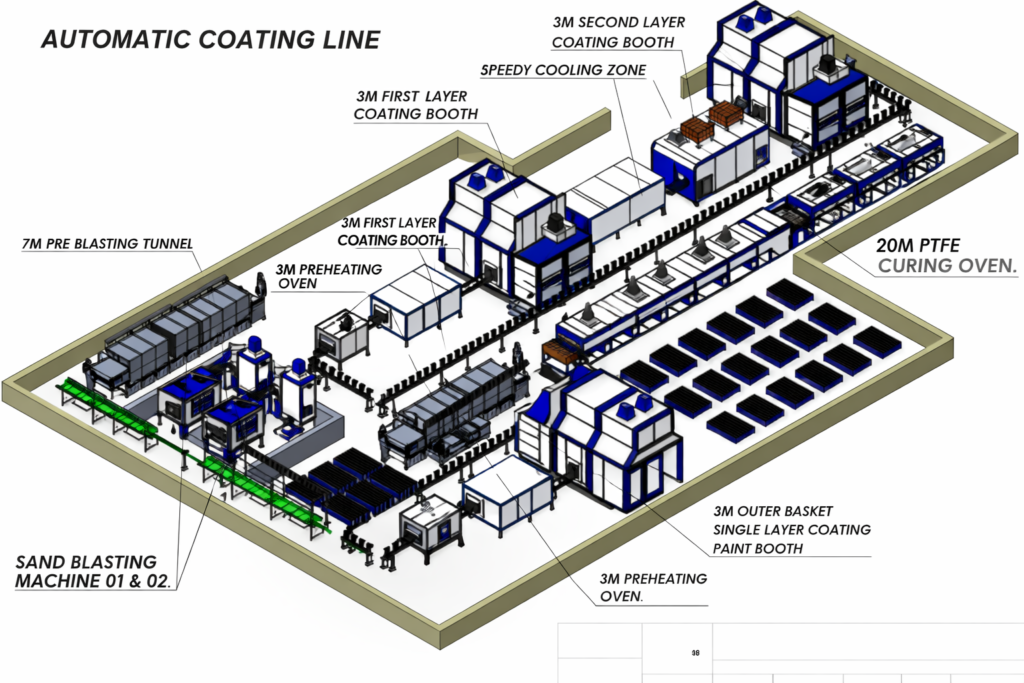

Kratos designs and manufactures robust, modular conveyor systems that integrate seamlessly with automatic coating lines and assembly operations. Built for reliability and flexibility, our conveyors support varied load capacities, adjustable speeds, and ergonomic working heights, enabling consistent material flow and improved operator productivity.

With precision-engineered structures and advanced drive options, Kratos conveyor systems deliver stable performance in continuous industrial operations.

Assembly Conveyors

Kratos Assembly Conveyors are engineered to support efficient assembly, inspection, and finishing operations. Designed with operator ergonomics in mind, these conveyors provide adjustable working heights, integrated lighting, and optional operator cooling for enhanced comfort and productivity.

| Description | Specification |

|---|---|

| Load Capacity | 25 to 150 kg/m |

| Conveying Speed | 10 – 40 m/min |

| Incline / Decline | Up to 5° |

| Roller Type | Free-flow universal roller |

| Roller Diameter | Ø50 mm / Ø60 mm |

| Roller Material | Steel, 1.5 mm / 3 mm thickness, zinc-plated |

| Mounting Pitch (Top Roller) | 450 mm |

| Mounting Pitch (Return Roller) | 1200 mm |

| Rated Voltage | 230 V / 415 V |

| Motor Power | 0.5 kW to 5.0 kW |

| Motor Type | Geared motor |

| Conveyor Belt | Smooth PVC belt, 2-ply, longitudinally grooved (for incline) |

| Slider Bed | Steel sheet, 2 mm thickness |

| Between Frame (BF) | 600 / 800 / 1000 / 1200 / 1500 mm |

| Total Width | BF + 100 mm |

| Module Length | Up to 25,000 mm |

| Working Height | 700 ± 50 mm (adjustable); up to 2300 mm available |

| Station Lighting | LED task lights provided at each assembly station |

| Operator Cooling Fans | Individual air-circulation fans provided at each assembly station for operator comfort |

Powered Roller Conveyors

Kratos Powered Roller Conveyors are designed for controlled, reliable transport of components across production and logistics areas. The system supports accumulation, transfer, indexing, and sorting applications with a wide range of accessories.

| Description | Specification |

|---|---|

| Conveyor Type | Powered Roller Conveyor |

| Roller Tube Diameter | 50 / 60 / 80 / 90 / 100 mm |

| Roller Tube Material | Steel, Zinc-Plated, PU-Coated |

| Roller Type | Fixed Drive Roller |

| Roller Drive Head | Sprocket / Poly-Vee / Double-Groove Tube / Timing Pulley |

| Roller Mounting Pitch | 75 / 90 / 100 / 120 mm |

| Conveyor Length | 1 m to 15 m |

| Maximum Module Length | Up to 3 m |

| Conveyor Width | 300 mm to 1200 mm |

| Conveyor Height | 300 mm to 2400 mm |

| Conveying Capacity | 30 / 50 / 75 / 125 kg per meter (max) |

| Conveyor Speed | 5 to 90 m/min |

| Conveyor Drive | AC Geared Motor / Powered Roller |

| Inclination Angle | 5° to 10° (maximum) |

| Side Guide Type | Steel Wheel / Round Tube / U-Channel |

| Side Guide Height | 50 / 150 / 300 / 600 mm |

| Conveyor Accessories | Safety covers, photoelectric sensors with brackets, cable trays, bottom covers, roller gap covers, channel side covers, stoppers, pop-up units, diverters, singulators, tilting units, indexing units, TOD |

| Speed Control | VFD / Roller Drive Card |

| Conveyor Frame | High-quality CRC steel sheet, CNC laser-cut and bent into C-profile with collar bends, slotted flanges, and defined mounting holes |

| Conveyor Legs | CRC steel, CNC laser-cut C-profile with height-adjustment slots, angle-alignment brackets, and base plates with grouting holes |

Chat to our team

Chat with our automation specialists for quick answers, product guidance, or help finding the right solution for your cookware manufacturing needs.

Why Manufacturers Trust

Kratos Automations

We’re not just machine builders—we’re automation partners. With deep industry focus, tailored engineering, and proven results across global factories, Kratos helps cookware manufacturers work smarter, faster, and more efficiently.

Industry-Specific Expertise

We specialize exclusively in cookware manufacturing automation. From coating lines to grooving machines, our solutions are purpose-built—not repurposed.

Custom Engineering for Every Plant

No two factories are the same. That’s why we design, build, and fine tune every system to match your specific process, space, and production goals.

Reliable Support & Global Reach

We serve clients across India, the Middle East, and Southeast Asia with fast, responsive technical support and long-term maintenance you can count on.

Automation Solutions for Every Coating Line

Have questions about our automation systems, installation process, or capabilities? We’ve answered the most common queries to help you better understand how Kratos can support your cookware manufacturing goals.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.