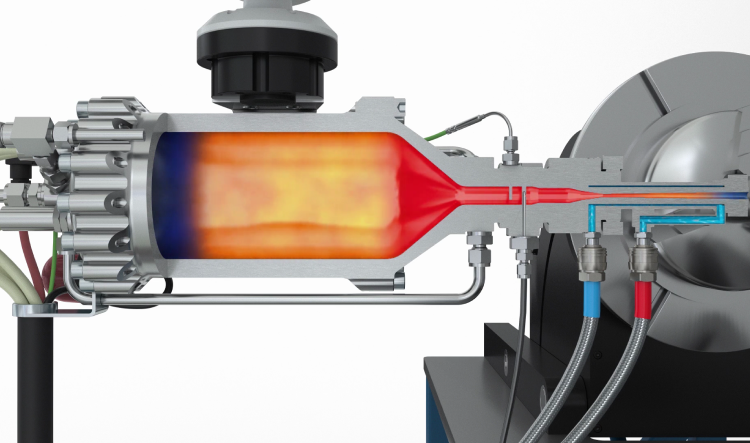

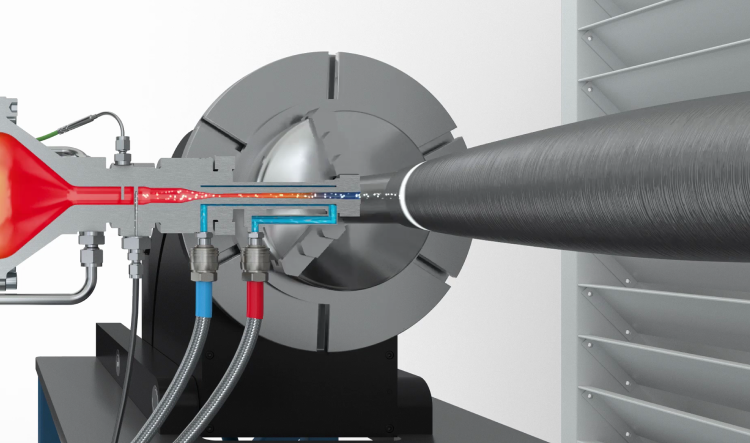

How Cold Spraying Works?

Cold spraying is an advanced coating process where metal powders are accelerated through a high-speed gas stream and bonded to a surface—without using heat. This preserves the base material’s integrity while creating dense, durable coatings ideal for cookware, aerospace, and more.

Discover the power of cold spray technology

See how our advanced cold spray system delivers high-performance coatings without heat distortion. Watch the video to learn how this innovative process boosts durability, precision, and production efficiency—ideal for cookware and industrial applications.

Understanding Cold Spray Technology

Cold spraying is a solid-state coating process where fine particles are accelerated at high speeds to form strong, dense layers—without melting the material. The quality of the coating depends on precise control of particle velocity, making it ideal for sensitive, high-performance applications.

Critical Speed – The Bonding Threshold

For a coating particle to bond effectively to the surface, it must strike at or above a specific minimum velocity called the critical speed. This value differs for each material and is essential for strong adhesion.

Above Critical Speed – Improved Adhesion

Once the particle exceeds its critical speed, deformation increases at impact—enhancing the mechanical interlock between the coating and the component for a tighter, more durable bond.

Erosion Speed – When Too Much is Harmful

If particles travel too fast and reach erosion speed, they may start to damage the surface, causing material loss instead of forming layers—compromising coating quality.

The Optimal Range – Strong and Stable Layers

The best coating results happen when particle velocities stay between critical and erosion speeds. This balance ensures dense, robust coatings with high performance and durability.

What Makes Cold Spray Technology Unique

Cold spraying is a cutting-edge surface coating process that uses high-velocity gas to apply material without melting it. This solid-state approach delivers superior coating quality, excellent material retention, and outstanding versatility—ideal for precision-critical industries like cookware, aerospace, and automotive.

No Heat Distortion

Cold spraying is a solid-state coating process, meaning the particles never melt. This eliminates the thermal stress, warping, or microstructural changes typically caused by high-temperature processes. As a result, sensitive components can be coated without risk of damage, preserving their mechanical and chemical integrity. It’s a perfect solution for applications where heat exposure is unacceptable, such as aerospace parts, cookware surfaces, or precision tools.

Automation Solutions for Every Coating Line

Have questions about our automation systems, installation process, or capabilities? We’ve answered the most common queries to help you better understand how Kratos can support your cookware manufacturing goals.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Get Expert Advice, Industry Trends, and

Automation Insights – All in One Place

Stay updated with expert insights, real-world case studies, and the latest trends in cookware manufacturing automation. Whether you’re upgrading a single machine or planning a full plant transformation, our articles deliver the knowledge you need to move smarter and faster.