Automatic Shot Blasting Machines for Surface Preparation

Kratos Shot Blasting Machines are engineered to deliver uniform, controlled surface preparation that significantly enhances coating adhesion, durability, and overall finish quality. Designed for integration with automatic coating lines, our systems ensure consistent roughness, stable throughput, and reliable performance in demanding industrial environments.

Kratos shot blasting systems are designed to prepare metal surfaces precisely before coating, removing oxides, scale, and surface contaminants while creating the optimal roughness profile for strong coating adhesion. Using high-pressure reciprocating air blasting with aluminium oxide media, the machines deliver repeatable results across a wide range of cookware and industrial components.

With PLC-based automation, configurable blasting guns, and efficient dust extraction, the system ensures process consistency, operator safety, and long service life.

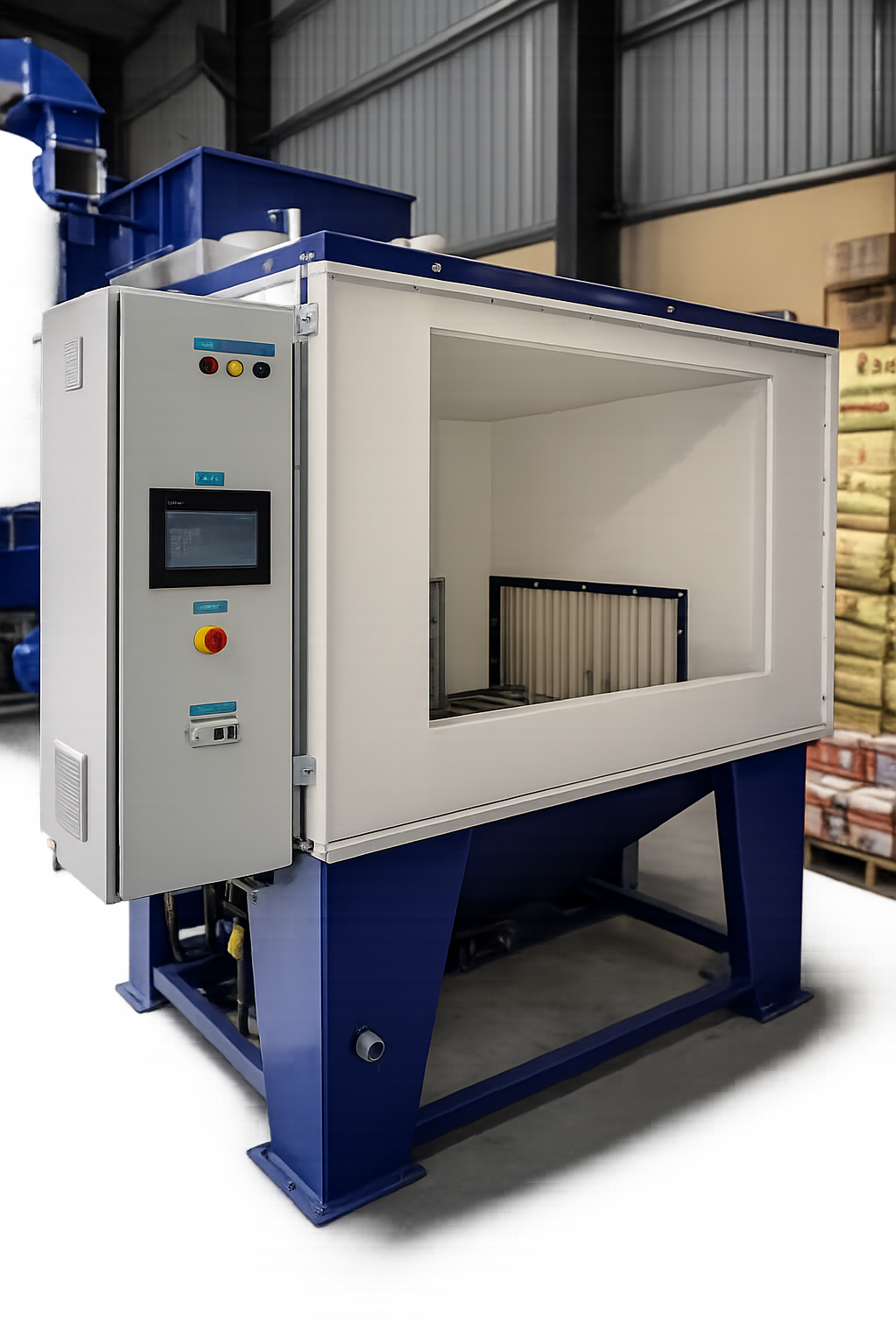

Model 1

Kratos Shot Blasting Machines are designed to provide uniform and controlled surface preparation essential for high-quality coating applications. Available in high-capacity and medium-capacity configurations, these systems use high-pressure reciprocating air blasting with aluminium oxide media to achieve consistent surface roughness and improved coating adhesion. With PLC-based automation, configurable blast guns, efficient dust collection, and robust safety features, Kratos shot blasting machines deliver reliable performance, low maintenance operation, and seamless integration into automatic coating lines.

| Parameter | Specification |

|---|---|

| Production Capacity | 500– 800 pieces per hour |

| Control & HMI System | PLC-based control system with color HMI touch panel for machine operation, parameter setting, alarms, and diagnostics |

| Blasting Method | Reciprocating Type High-Pressure Air Shot Blasting with Gun |

| Blast Media Type | Aluminium Oxide (as per application) |

| Operating Air Pressure | 5 to 7 bar (Adjustable) |

| Blasting Gun Type | Y-Type High-Performance Blast Gun |

| Number of Guns | 10 to 16 Nos. (Configurable) |

| Transportation Method | Multi Station Indexing Turntable |

| Loading Method | Manual / Automatic |

| Work piece Size | Diameter: 150 mm to 350 mm Height: 15 mm to 150 mm |

| Dust Collection System | Cartridge / Bag Filter Type with Automatic Pulse-Jet Cleaning |

| Surface Finish Achieved (Ra) | 1.5 to 5 Micron |

| Safety Features | Gun interlocks, wear-resistant blast cabinet lining, emergency stop system, No Cyclone Chamber |

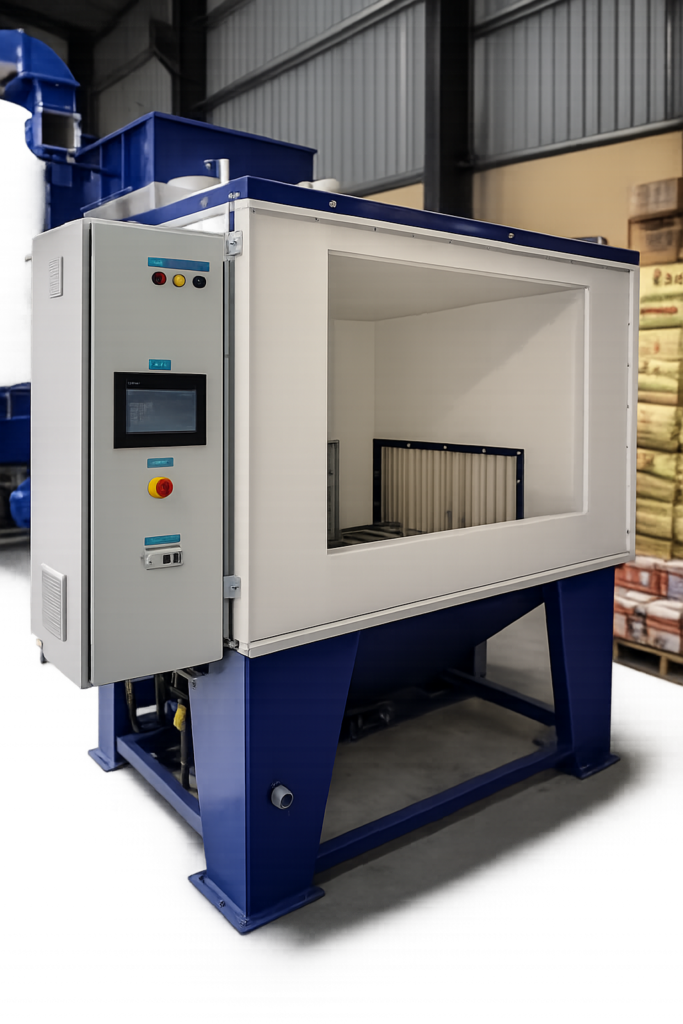

Model 2

Kratos Shot Blasting Machines are designed to provide uniform and controlled surface preparation essential for high-quality coating applications. Available in high-capacity and medium-capacity configurations, these systems use high-pressure reciprocating air blasting with aluminium oxide media to achieve consistent surface roughness and improved coating adhesion. With PLC-based automation, configurable blast guns, efficient dust collection, and robust safety features, Kratos shot blasting machines deliver reliable performance, low maintenance operation, and seamless integration into automatic coating lines.

| Parameter | Specification |

|---|---|

| Production Capacity | 100 – 450 pieces per hour |

| Control & HMI System | PLC-based control system with color HMI touch panel for machine operation, parameter setting, alarms, and diagnostics |

| Blasting Method | Reciprocating Type High-Pressure Air Shot Blasting with Gun |

| Blast Media Type | Aluminium Oxide (as per application) |

| Operating Air Pressure | 5 to 7 bar (Adjustable) |

| Blasting Gun Type | Y-Type High-Performance Blast Gun |

| Number of Guns | 2 to 8 Nos. (Configurable) |

| Transportation Method | Multi Station Indexing Turntable |

| Loading Method | Manual / Automatic |

| Work piece Size | Diameter: 150 mm to 300 mm Height: 15 mm to 150 mm |

| Dust Collection System | Cartridge / Bag Filter Type with Automatic Pulse-Jet Cleaning |

| Shot Recovery System | Cyclone Chamber with Abrasive Separation |

| Surface Finish Achieved (Ra) | 1.5 to 5 Micron |

| Safety Features | Gun interlocks, wear-resistant blast cabinet lining, emergency stop system |

Chat to our team

Chat with our automation specialists for quick answers, product guidance, or help finding the right solution for your cookware manufacturing needs.

Why Manufacturers Trust

Kratos Automations

We’re not just machine builders—we’re automation partners. With deep industry focus, tailored engineering, and proven results across global factories, Kratos helps cookware manufacturers work smarter, faster, and more efficiently.

Industry-Specific Expertise

We specialize exclusively in cookware manufacturing automation. From coating lines to grooving machines, our solutions are purpose-built—not repurposed.

Custom Engineering for Every Plant

No two factories are the same. That’s why we design, build, and fine tune every system to match your specific process, space, and production goals.

Reliable Support & Global Reach

We serve clients across India, the Middle East, and Southeast Asia with fast, responsive technical support and long-term maintenance you can count on.

Automation Solutions for Every Coating Line

Have questions about our automation systems, installation process, or capabilities? We’ve answered the most common queries to help you better understand how Kratos can support your cookware manufacturing goals.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.