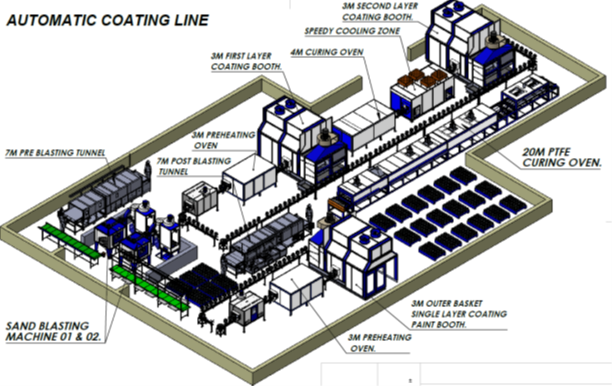

Automatic Coating Line Solutions for Cookware & Bakeware Manufacturing

Kratos Automations delivers fully integrated automatic coating line solutions designed for high-volume, high-quality cookware and bakeware production. Our systems combine precision surface preparation, advanced coating technologies, controlled curing, and intelligent automation to ensure consistent performance, superior finish, and optimized productivity.

Kratos Automatic Coating Lines are end-to-end turnkey solutions covering every stage from press shop interfacing to final assembly and packing. Designed for outputs of 400 to 1,000 pieces per hour, these lines integrate washing, shot blasting, coating booths, curing ovens, conveyors, robotics, and PLC-based controls into a single synchronized system.

With modular design and flexible configurations, the solution supports PTFE, ceramic/sol-gel, and electrostatic bakeware coating processes, ensuring repeatable quality, reduced manual intervention, and long-term operational reliability.

Non-Stick Automatic Spray Coating Lines (PTFE)

Kratos PTFE Automatic Spray Coating Lines are engineered to meet the stringent process requirements of multi-layer PTFE coatings, ensuring excellent adhesion, controlled film build, and consistent non-stick performance. Precise control over spray parameters, gun positioning, and conveyor speed ensures repeatable results across primer, mid-coat, and top-coat layers.

| Parameter | Specification |

|---|---|

| Production Capacity | 600 – 1,000 pieces per hour |

| Control & HMI System | PLC-based control system with color HMI touch panel for machine operation, parameter setting, alarms, and diagnostics |

| Conveyor Speed | 0 to 5m/min (variable) |

| Work piece Size | Diameter: 150 mm to 450 mm Height: 15 mm to 150 mm |

| Spraying Method | Fixed Gun System / Robotic Spray |

| Transportation Method | Track Chain Conveyor |

| Loading Method | Manual |

| Curing Temperature Range | 400°C to 450°C (Adjustable) |

| Curing Oven | Electric heating with thyristor-based controller for precise temperature control and high energy efficient |

| Stage configuration | Loading → De-dusting → Base Coat → Flash-off Oven → Mid Coat → Top Coat → Curing Oven → De-dusting → Exterior Coating → Final Curing Oven→ Un Loading |

Electrostatic Bakeware Coating Lines

Kratos electrostatic bakeware coating lines are engineered for high-efficiency, durable non-stick coatings on trays, pans, and complex bakeware shapes. The system combines electrostatic spray technology, optimized airflow, and controlled curing to achieve uniform coverage, superior wrap-around, and long-lasting coating performance aligned with global bakeware standards.

| Parameter | Specification |

|---|---|

| Production Capacity | 600 – 1,000 pieces per hour |

| Control & HMI System | PLC-based control system with color HMI touch panel for machine operation, parameter setting, alarms, and diagnostics |

| Conveyor Speed | 0 to 5m/min (variable) |

| Work piece Size | Diameter: 150 mm to 450 mm Height: 15 mm to 150 mm |

| Spraying Method | Fixed Gun System / Robotic Spray |

| Transportation Method | Track Chain Conveyor |

| Loading Method | Manual |

| Curing Temperature Range | 400°C to 450°C (Adjustable) |

| Curing Oven | Electric heating with thyristor-based controller for precise temperature control and high energy efficient |

| Stage configuration | Loading → De-dusting → Base Coat → Flash-off Oven → Mid Coat → Top Coat → Curing Oven → De-dusting → Exterior Coating → Final Curing Oven→ Un Loading |

Non-Stick Ceramic & Sol-Gel Coating Solutions

Developed for precision thin-film application, Kratos ceramic and sol-gel coating solutions ensure premium surface finish, controlled coating thickness, and enhanced non-stick properties. With stable thermal processing and automated spray control, the system delivers repeatable quality, reduced rejection, and consistent throughput for modern cookware production.

| Parameter | Specification |

|---|---|

| Production Capacity | 600 – 1,000 pieces per hour |

| Control & HMI System | PLC-based control system with color HMI touch panel for machine operation, parameter setting, alarms, and diagnostics |

| Conveyor Speed | 0 to 5m/min (variable) |

| Work piece Size | Diameter: 150 mm to 450 mm Height: 15 mm to 150 mm |

| Spraying Method | Fixed Gun System / Robotic Spray |

| Transportation Method | Track Chain Conveyor |

| Loading Method | Manual |

| Curing Temperature Range | 400°C to 450°C (Adjustable) |

| Curing Oven | Electric heating with thyristor-based controller for precise temperature control and high energy efficient |

| Stage configuration | Loading → De-dusting → Base Coat → Flash-off Oven → Mid Coat → Top Coat → Curing Oven → De-dusting → Exterior Coating → Final Curing Oven→ Un Loading |

Chat to our team

Chat with our automation specialists for quick answers, product guidance, or help finding the right solution for your cookware manufacturing needs.

Why Manufacturers Trust

Kratos Automations

We’re not just machine builders—we’re automation partners. With deep industry focus, tailored engineering, and proven results across global factories, Kratos helps cookware manufacturers work smarter, faster, and more efficiently.

Industry-Specific Expertise

We specialize exclusively in cookware manufacturing automation. From coating lines to grooving machines, our solutions are purpose-built—not repurposed.

Custom Engineering for Every Plant

No two factories are the same. That’s why we design, build, and fine tune every system to match your specific process, space, and production goals.

Reliable Support & Global Reach

We serve clients across India, the Middle East, and Southeast Asia with fast, responsive technical support and long-term maintenance you can count on.

Automation Solutions for Every Coating Line

Have questions about our automation systems, installation process, or capabilities? We’ve answered the most common queries to help you better understand how Kratos can support your cookware manufacturing goals.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Can Kratos automate my entire cookware production line?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What types of coatings are supported?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s,

What regions do you serve?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.